A floor could have the most intricate, colourful and artistic pattern across its finish, but if the underlying substrate has not been properly analysed then it could quickly become a blistered, cracked and unsightly mess.

Moisture lurking below the floor finish can pose a serious risk to the building’s finish. If a damp proof membrane (DPM) is not installed then the moisture will try to rise out of the floor regardless of what is in its way.

To help you work out if a DPM is required, and if so of what sort, we’ve compiled the following advice on this often unseen but critical part of the floor build up.

What Does a DPM Do?

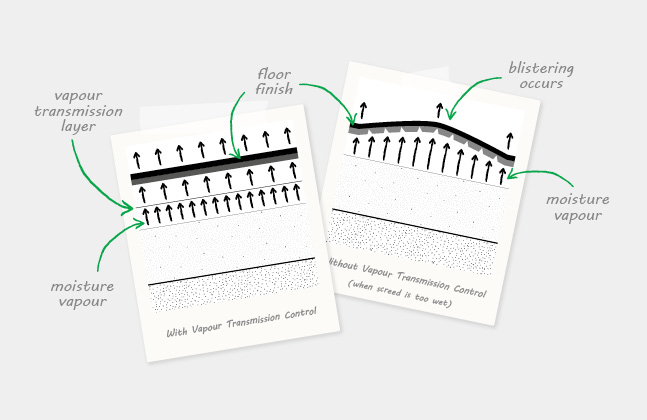

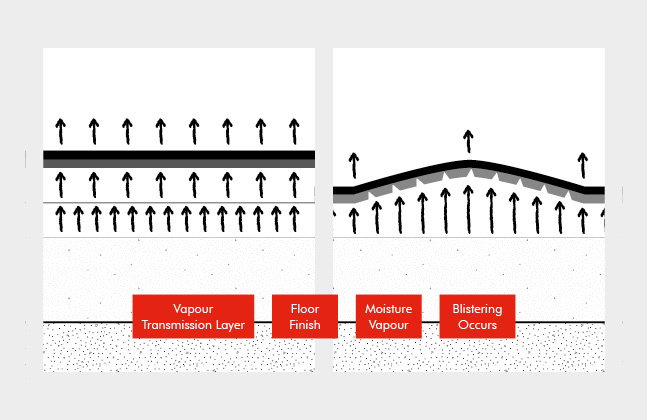

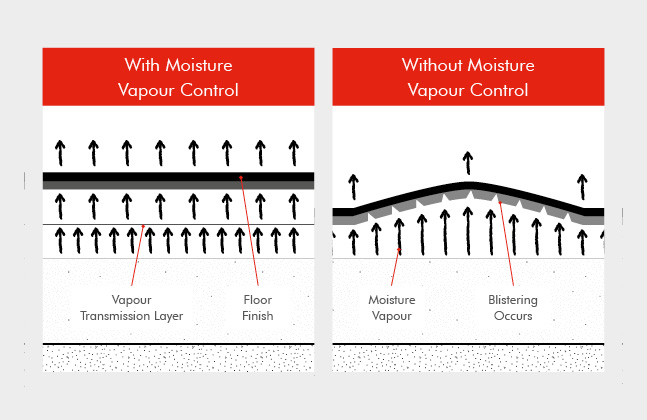

Trapped residual moisture within the concrete or screed is drawn to the surface, which can result in hydrostatic pressure forcing up the finish. If there isn’t a DPM then this will show itself as unpleasant blistering across the floor area.

A DPM effectively slows down and evens out the rate at which the moisture is released. This avoids blistering as the moisture vapour transmission emanates out of the floor equally, instead of being concentrated into pockets.

Testing the Floor’s Moisture Level

The Resin Flooring Association (FeRFA) guidelines stipulate that a DPM will be required if there is more than 4 grams of water per cubic centimetre passing through the substrate in a day.

To ascertain if this is the case, there are two main techniques for testing a substrate’s moisture level, which involves using either a needle type or a surface mounted hygrometer.

A needle hygrometer is effectively a thermometer style instrument that is drilled into the screed, however a surface mounted hygrometer is often perceived as the more practical option, as it doesn’t stick out so much which means it is less likely to be knocked and broken on a busy construction site.

A surface mounted hygrometer is glued to the surface to create an airtight seal, creating a dry environment for the instrument to read the floor. It should then be monitored, typically over the course of a week, until a constant reading is achieved.

What DPM is Required?

If the hygrometer reading comes back above 75% relative humidity (RH) then a liquid DPM needs to be applied.

The specific liquid DPM system will depend on the type of substrate or screed. For a self-levelling screed a system such as Flowcrete UK’s Hydraseal would be used. This is a solvent, water free, epoxy resin and moisture tolerant curing agent that allows for immediate installation of moisture sensitive floor finishes onto concrete and cementitious screeds which have a moisture content with a RH of up to 100%.

Alternatively if a semi-dry cementitious screed, such as K-Screed, has been laid down, then Isocrete M-Bond would be used as this has been designed to work specifically with semi-dry screeds.

For osmotic residual moisture FeRFA says that a DPM must not allow moisture to move through it at any more than 4 grams per m3 in a day. If it’s higher than this then the DPM is not effective.

When the level of water is more than a liquid DPM will be able to deal with, for example if the site is on a high water table, then a sheet membrane will be required to stop the rising water. This sheet membrane will need to be installed beneath the structural concrete to ensure that the hydrostatic pressure doesn’t affect the floor finish.

To find out more about installing a damp proof membrane, get in touch with Flowcrete UK’s resin flooring experts by calling 01270 753000 or emailing ukweb@flowcrete.com.