You don’t need to be an avid All Things Flooring reader to know that we love to talk flooring, and whilst all of our authors and contributors have expertise in the flooring industry, it is rare that we get insights from the architects who design spaces and specify why particular flooring systems are chosen. Luckily, our team were fortunate enough to gather such insights from Rogers Stirk Harbour + Partners, the architectural practice behind Scottish whisky distillery The Macallan.

Find out all about The Macallan in our project overview post here.

Described by the project director as “building a skyscraper on its side in the Highlands”, it was clear to see from the start that no ordinary site would do for The Macallan’s distillery. Rather than your average food and beverage facility, Edrington, the international spirits group that owns The Macallan, wanted to build an architectural monument on The Macallan’s traditional Speyside estate, to house both a distillery and visitor centre.

The Macallan looks more like an art exhibition than a food and beverage facility

Toby Jeavons, Project Architect and Associate Partner at Rogers Stirk Harbour + Partners, said that: “The brief for the project was for a new production distillery and a new visitor experience. It was clear from the outset and key to our architectural concept of the building that these two functions be co-located under one unifying structure. The visitor experience spaces were always considered the reception to the distillery and not a separate area or building where one learns about a production process abstractly and in isolation. The reception presents the visitor with a 10-metre-tall glazed wall which allows all to see into the deep inner workings of the distillery.”

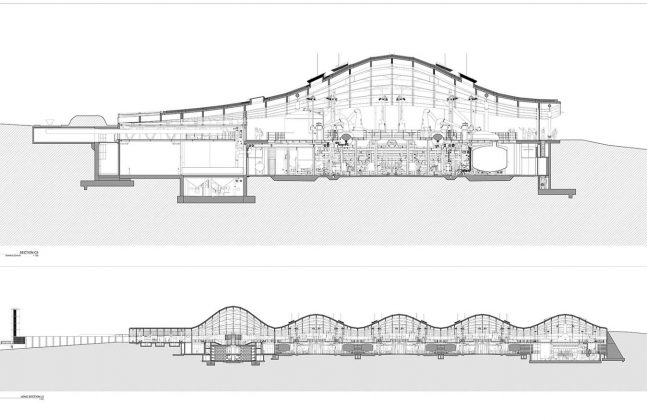

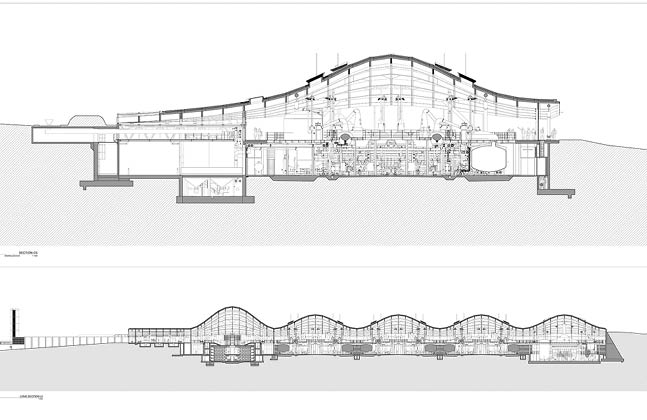

Rogers Stirk Harbour + Partners Architect Drawing of The Macallan

The floor’s aesthetic was a critical aspect of this project, as it had to tie into the site’s image while emphasising the flow between the industrial and commercial aspects of the site. Visitors to The Macallan’s whisky tour would not just experience resin flooring in the production areas, as decorative resin finishes were also applied across many other parts of the site’s visitor centre and distillery tour.

Toby Jeavons goes on to say: “The distillery is ‘the’ exhibit and the reason for the visit. Therefore, the use of a resin floor finish throughout all of the visitor experience and working areas deliberately blurs the lines between ‘front of house’ and the production beyond.”

Within the production area and main internal tourist routes this blurring of lines was helped with the use of a sleek dark grey flooring that reflected the industrial tones and hues of the site while conveying a contemporary, stylish ambience.

Rogers Stirk Harbour + Partners

Whilst the same hues were used across the site, the properties of the flooring types differed to suit the areas that they were used for. The production area for example needed flooring that could withstand exposure to yeast, varying temperatures and spillages as well as heavy equipment, whereas the pathways used by visitors did not need such properties.

Toby Jeavons summed up this ethos: “A resin floor finish was the natural choice within the distillery production areas for its uniform aesthetic, robust industrial performance and corrosion resistance. The application of this product could have proved problematic, having to negotiate various elements of structure, process pipework and equipment, however the use of Flowfast HF has been extremely successful and was clearly the correct choice for the location. For the accessible visitor areas, a Flowfresh Quartz resin was used for its easier application over large areas and lower chemical resistance, however the texture and tonal qualities compliment the production locations very well.”

For the production areas, 5,570 m2 of the thick polyurethane resin floor screed Flowfresh HF LT was used thanks to it being HACCP Internationally certified and ISO 22916 accredited. The high chemical resistance and incorporation of Polygiene®, an antibacterial additive was also useful here, as spillages could be cleaned up without the risk of missed bacteria growing and multiplying, and with no risk to the floor’s finish.

Flowfresh HF LT was used in the production areas of the facility

If you have read our previous post on the cask room, you’ll already know that the visuals in this area were vital in creating a private cellar that displays casks like a gallery exhibition. Toby Jeavons describes the space as:

“This acts as a centre piece exhibit and the ‘holy of holies’ for visitors and fans on the Macallan pilgrimage…The design required that both the ceiling and floor of this space be black in colour and highly reflective so providing the illusion of an endless array of vertical casks. The use of a black coloured Peran SL has again achieved this aim very successfully.”

Peran SL from Flowcrete UK was used to achieve this high gloss finish. This perfectly reflected both the casks and the cellar’s lights, to create a dynamic and seemingly endless aesthetic.

The reflective flooring and ceiling gives a seemingly endless visual

In addition, Flowcrete UK’s fast curing methyl methacrylate (MMA) resin floor topping Flowfast Quartz Structure was applied on the internal tourist routes and suspended walkways.

Using resin flooring ensured that the floors in the industrial spaces would maintain a functional, visually attractive finish for the long term. The robust, chemical resistant properties of the chosen systems would be able to withstand the onsite conditions and provide additional benefits such as easy cleanability, slip resistance and an in-built antibacterial agent. Similarly, the tourist routes would have to be tough enough to withstand foot traffic from the anticipated 50-60,000 annual visitors.

With the distillery now open for visitors you can see its incredible architecture first hand. If you would like to know any more on any of the systems mentioned above, please leave a comment below and our flooring specialists will get back to you.